- Expertise

- Mining

Adding Value, Optimizing Projects Utilizing Advanced Knowledge

Development of mining projects is becoming more challenging and less profitable as a result of low grade and deep mineral resources. A successful mining project requires technical know-how, practical experience and long-term perspective.

Sedgman Novopro’s specialized expertise for carrying out Mining projects from early-stage exploration through development and operations to closure, includes:

-

Mineral Exploration, Geology and Resource Modeling

Mineral Exploration, Geology and Resource Modeling

-

Mine Engineering, Design and Planning, Surface/Underground

Mine Engineering, Design and Planning, Surface/Underground

-

Mine Geotechnical Engineering

Mine Geotechnical Engineering

-

Mine Water Management

Mine Water Management

-

Tailings Storage and Management

Tailings Storage and Management

-

Environmental, Social assessments and Mine Closure

Environmental, Social assessments and Mine Closure

-

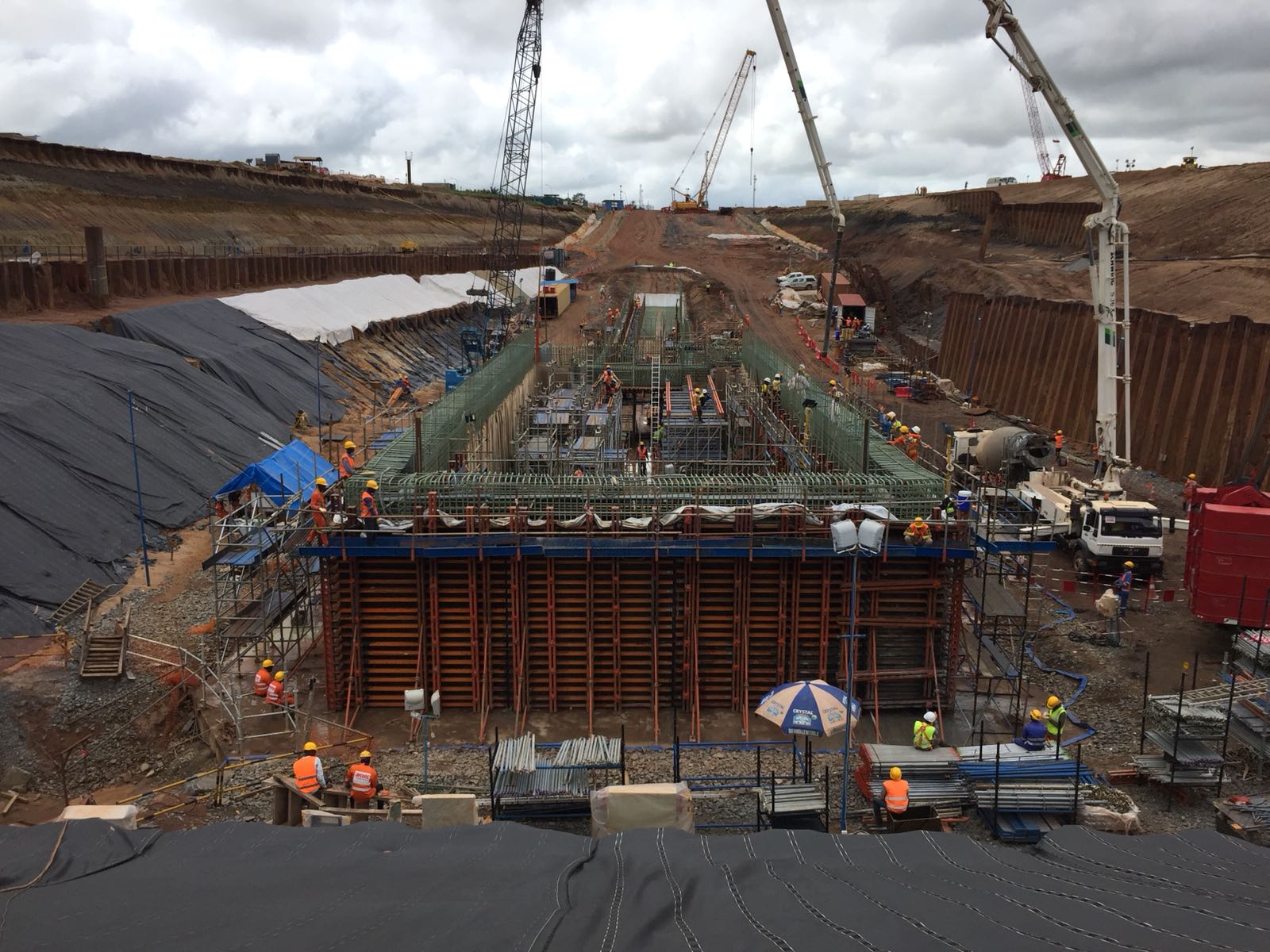

Mine Infrastructures and Civil Engineering

Mine Infrastructures and Civil Engineering

-

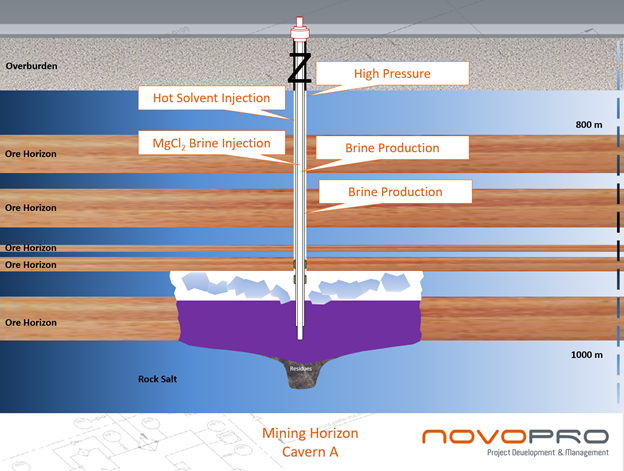

Solution Mining

Solution Mining

-

Brine Recovery via Playa or Paleochannel

Brine Recovery via Playa or Paleochannel