- Expertise

- MINERAL PROCESSING

Intelligent Approaches Overcomes Economic and Environmental Challenges

The world is experiencing high demand for metals, and low-grade ore deposits have become more profitable even with complex metallurgy. These provide a special opportunity to focus on environmental, energy saving and lower carbon emission aspects, leading to the innovative operating concepts and significant technological advances.

Sedgman Novopro has gained an extensive understanding for Mineral Processing design and implementation through the completion of numerous greenfield projects, expansion of brownfield operations as well as optimizations of existing flow sheets.

The experts at Sedgman Novopro deliver Mineral Processing solutions that combine simplicity with cutting-edge technologies in a widespread of sectors from alkali metals to base and precious metals from metallurgical sample identification to engineering, construction and commissioning. We can also act as an owner’s engineer to mentor and support your operations personnel.

Sedgman Novopro’s Mineral Processing expertise from exploration to production include:

Testing, Piloting and Geometallurgy

Metallurgical/mineralogical lab and pilot testing are the foundation of project development, demonstrating the project viability and providing key input data for flow sheet development. Our value lies in how we utilize the test-work data in Geometallurgical modelling to optimize mineral processing flow sheets and mining plans.

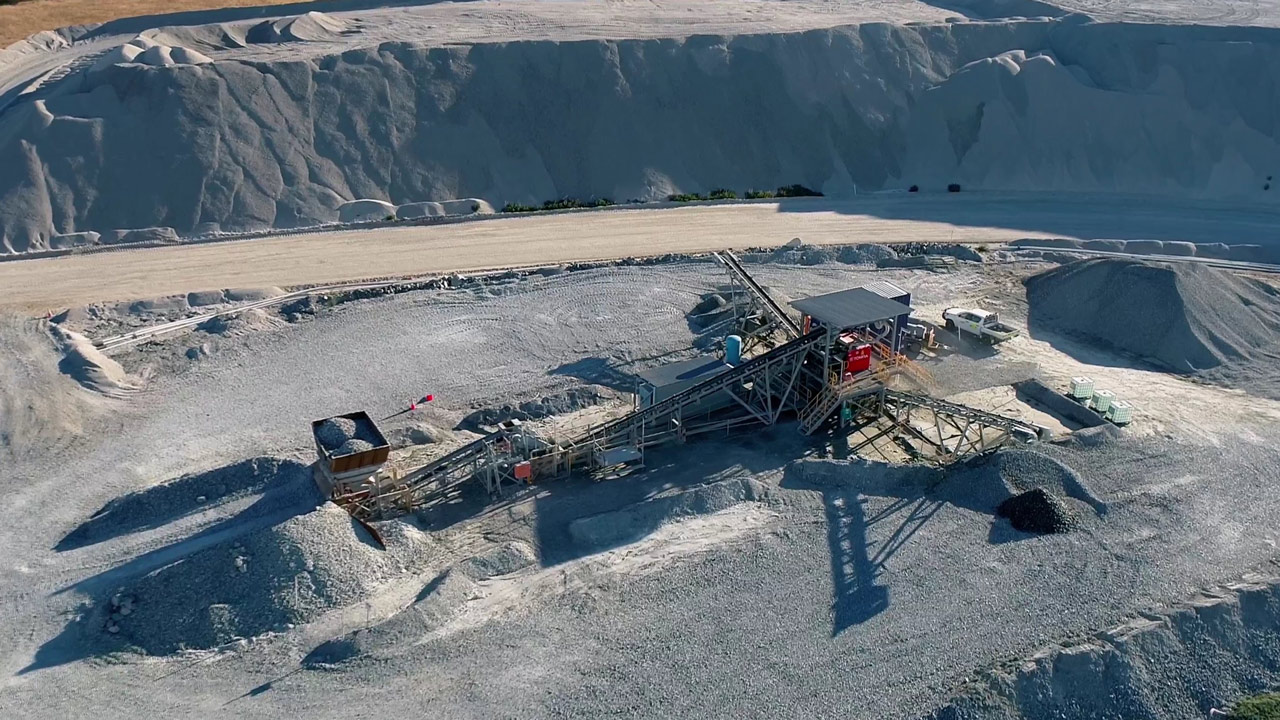

Comminution

Our experts have gained vast experience in a wide range of crushing, grinding, classification technologies from flow sheet development, modeling, optimization and design of circuits through to selecting and sizing the equipment and applying monitoring and control systems.

Pre-Concentration

Sedgman Novopro's metallurgical experts are experienced in Dry Pre-concentration on bulk/particle Ore Sorting and Run of Mine Ore Upgrading using Machine Learning techniques and based on heterogenic characteristics of minerals. The pre-concentration process enables mining rates to increase without needing to expand plants or increase the grade of the plant feed for higher recovery. There are many water/energy savings and technical, environmental, economic benefits of rejecting waste material before it reaches the process plant.

Beneficiation by gravity, magnetic, or heavy media separation

Our specialists have a comprehensive range of skills in all types of physical Beneficiation technologies including magnetic, gravity and heavy media separation in different minerals such as Iron Ore, Gold, chromite, etc. This includes all stages of testing, piloting and process development to commissioning and operation.

Flotation

We have hands-on experience with all types of flotation circuits incorporating conventional, column, and novel flotation equipment. This covers a diverse range of projects with concentrators operating at different capacities, involving a wide range of fertilizers, alkali metals, base and precious metals and industrial minerals.

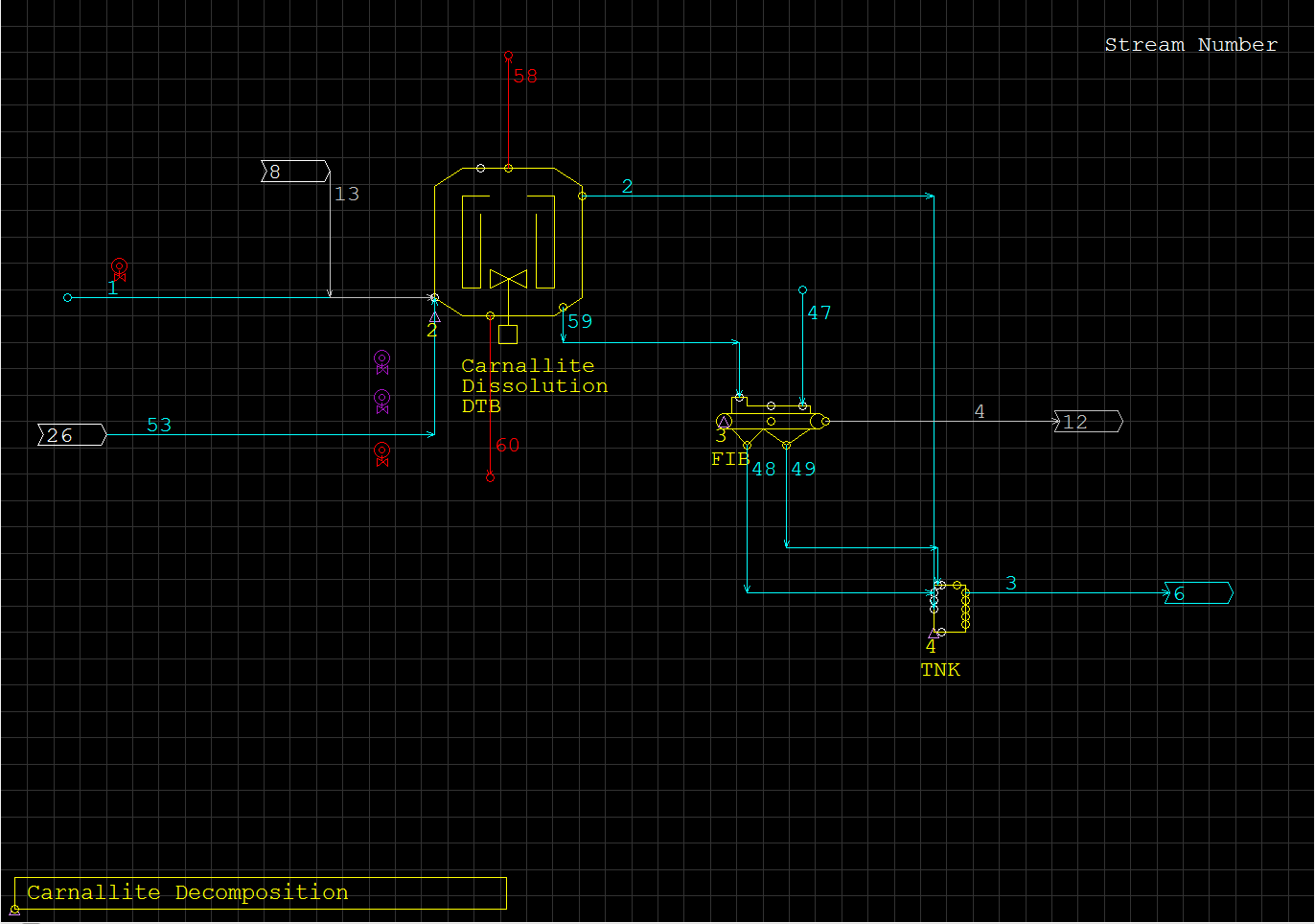

Hydrometallurgy

Our extensive skills incorporate all types of Leaching technologies such as In-Situ, Heap, Vat, Tank and Autoclave, followed by Solution Concentration and Purification involve Solvent Extraction and Ion Exchange technics, ending up with Mineral Recovery using Electrowinning, Precipitation, Neutralization, Membranes, Solar and Mechanical Evaporation.

Dewatering and Solid-Liquid Separation

We have extensive knowledge on dewatering and solid–liquid separation as an important part of our historical experience in fertilizer and alkali metal projects. It spans a range of stages, from feed preparation to concentrate handling and tailings disposal. Our experience in this area is extensive, and includes centrifuge, thickener and filter technologies from testing to specification and control.

Drying and Calcination

Experience in rotary or fluid bed drying and calcination from moderate to high temperature applications.

Compaction and Granulation

Experience with the detailed design of compaction and granulation projects as applied to fertilizer and related industries has given us the skills to help deliver: process consulting services, feasibility studies, technology evaluation, equipment selection, specialized equipment design and modeling.

Process Modelling and Optimization

Process Modelling and Optimization